Dyson launches air purifier with new sensing technology to destroy potentially dangerous indoor pollutants

Millions of people around the world are spending more time indoors. With all new solid-state formaldehyde sensing and sealed HEPA 13 standard,1 the new Dyson Purifier Formaldehyde range ensures a cleaner home environment.

22 March 2021

-

Whole-machine HEPA filtration

-

Precise formaldehyde sensing and destruction

Dyson unveiled its latest generation of purification machines with new solid-state formaldehyde sensing technology, designed to capture ultrafine dust and allergens, even destroying potentially dangerous VOCs including formaldehyde,2 launching in New Zealand on 20th May.

Formaldehyde is a colourless gas pollutant, released by furniture and wooden products containing formaldehyde-based resins like plywood and fibreboard, insulating materials and products such as paint, wallpapers, varnishes and household cleaning products.3 Being 500 times smaller than particles the size of 0.1 microns, it is particularly difficult to capture and if left undetected can lead to prolonged exposure due to continuous release of airborne chemicals, known as off-gassing.

While other gel-based formaldehyde sensors can deteriorate overtime and are easily confused with other VOC pollution, Dyson’s new, solid-state formaldehyde sensor works alongside Dyson’s unique algorithm to precisely monitor formaldehyde levels - intelligently ignoring other gases which are detected by a dedicated VOC sensor.

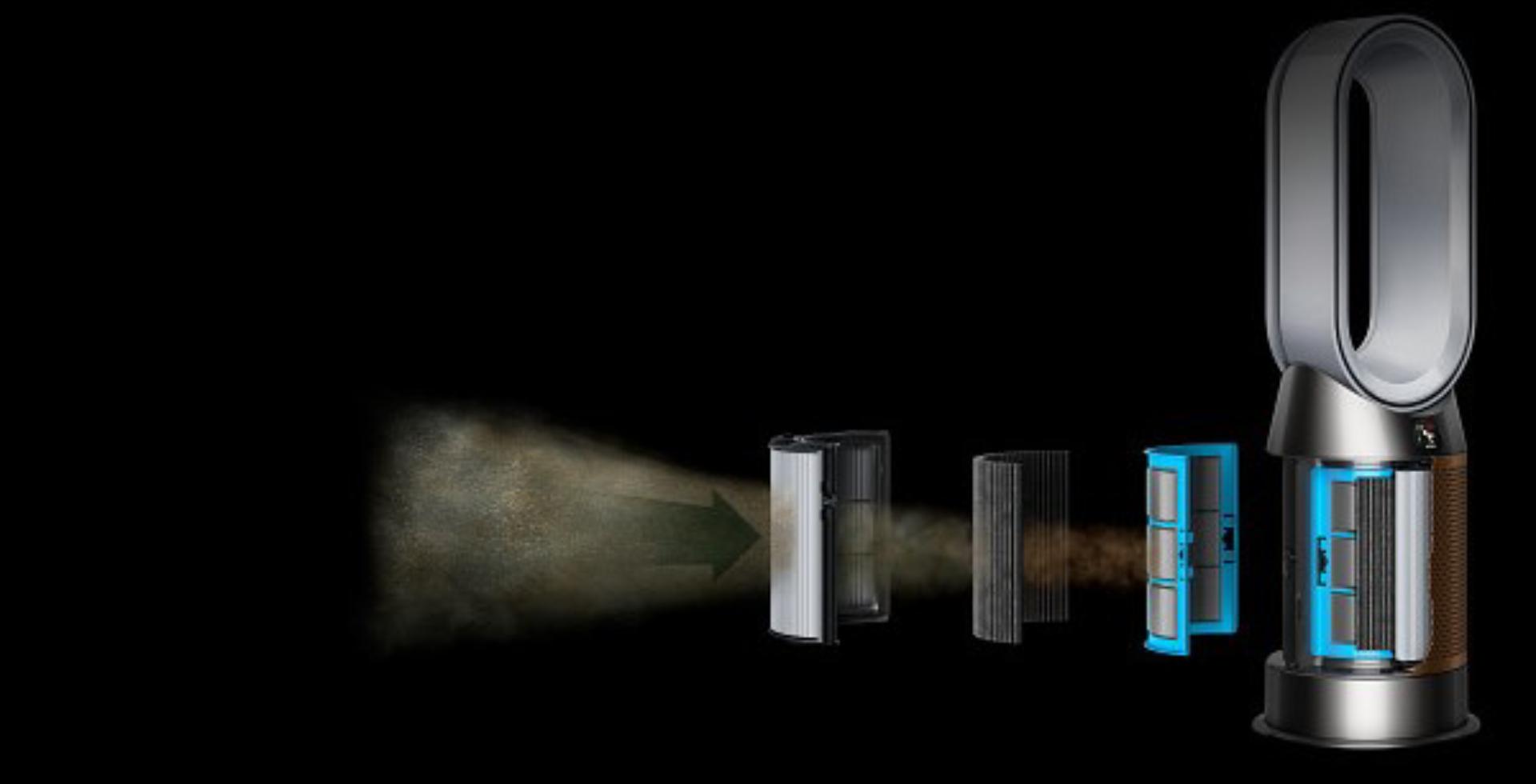

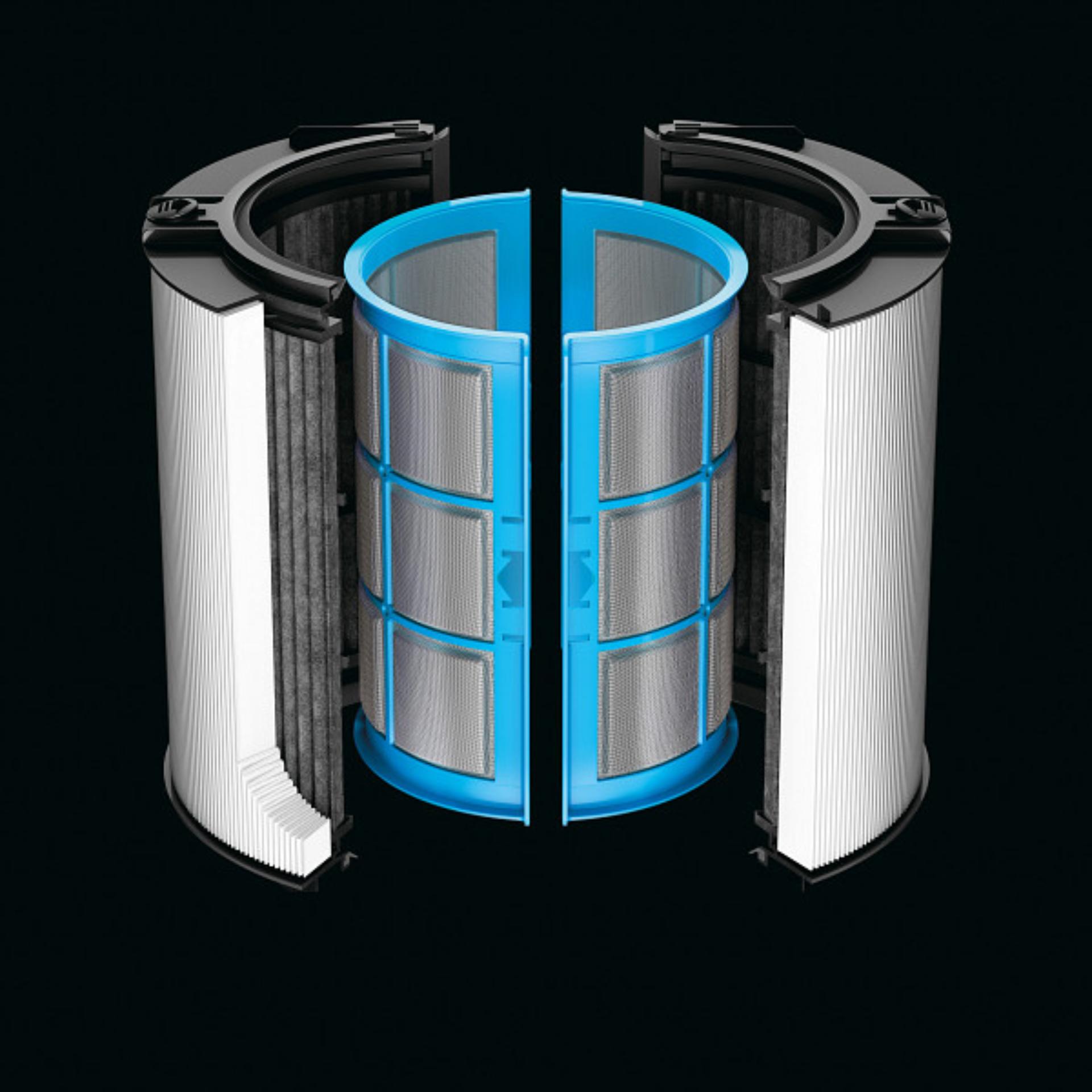

Tireless and ever-dissatisfied, Dyson engineers have also engineered the machine airflow pathways to achieve sealed HEPA 13 standard filtration – not only ensuring that no air bypasses the filter, but blocking any potential leak points through which dirty air might enter the airflow. This means Dyson purifiers remove 99.95% of particles as small as 0.1 microns.4

-

Dyson’s commitment to providing cleaner air

-

Alex Knox, Vice President of Environmental Care at Dyson said:

“The off-gassing tendency of formaldehyde means that it can go undetected in a home for years. Dyson has engineered a machine that provides accurate and successful sensing, capture and destruction of the pollutant. Our solid-state sensor doesn’t dry out overtime, lasting the lifetime of the machine. The COVID-19 pandemic has raised global awareness about the air that we breathe and Dyson’s commitment to providing cleaner air through innovation and technology remains at the forefront of our mission.”

The Indoor Generation

Every day, humans breathe up to 9,000 litres of air,5 and even before the COVID-19 pandemic spent as much as 90% of their time indoors.6 As our homes increasingly become spaces where we work and exercise as well as sleep and play, the quality of the air we breathe in all aspects of our routine is non-negotiable.

There are a number of indoor pollution sources, which release pollutants like PM10, PM2.5, VOCs, NO2 and formaldehyde into the air. Sources of pollution are present in all aspects of our daily lives, whether that be PM2.5 emitted when cooking, VOCs released from cleaning products or the continuous off-gassing of formaldehyde from our living room furniture. Tirelessly improving and constantly iterating, Dyson’s new Purifier Formaldehyde range reflects the latest technology in three core areas: sensing, filtration and acoustics.

-

Precise formaldehyde sensing and destruction

-

In addition to the existing particle, NO2, VOCs, temperature and humidity sensors, the integration of an intelligent formaldehyde sensor ensures precise sensing of the pollutant for the lifetime of the machine. Formaldehyde sensors can be gel-based and may deteriorate gradually as they dry out over time. Using an electro-chemical cell, the Dyson formaldehyde sensor does not dry out and its unique intelligent algorithm cross-checks data every second, selectively sensing to avoid confusion with other VOCs.

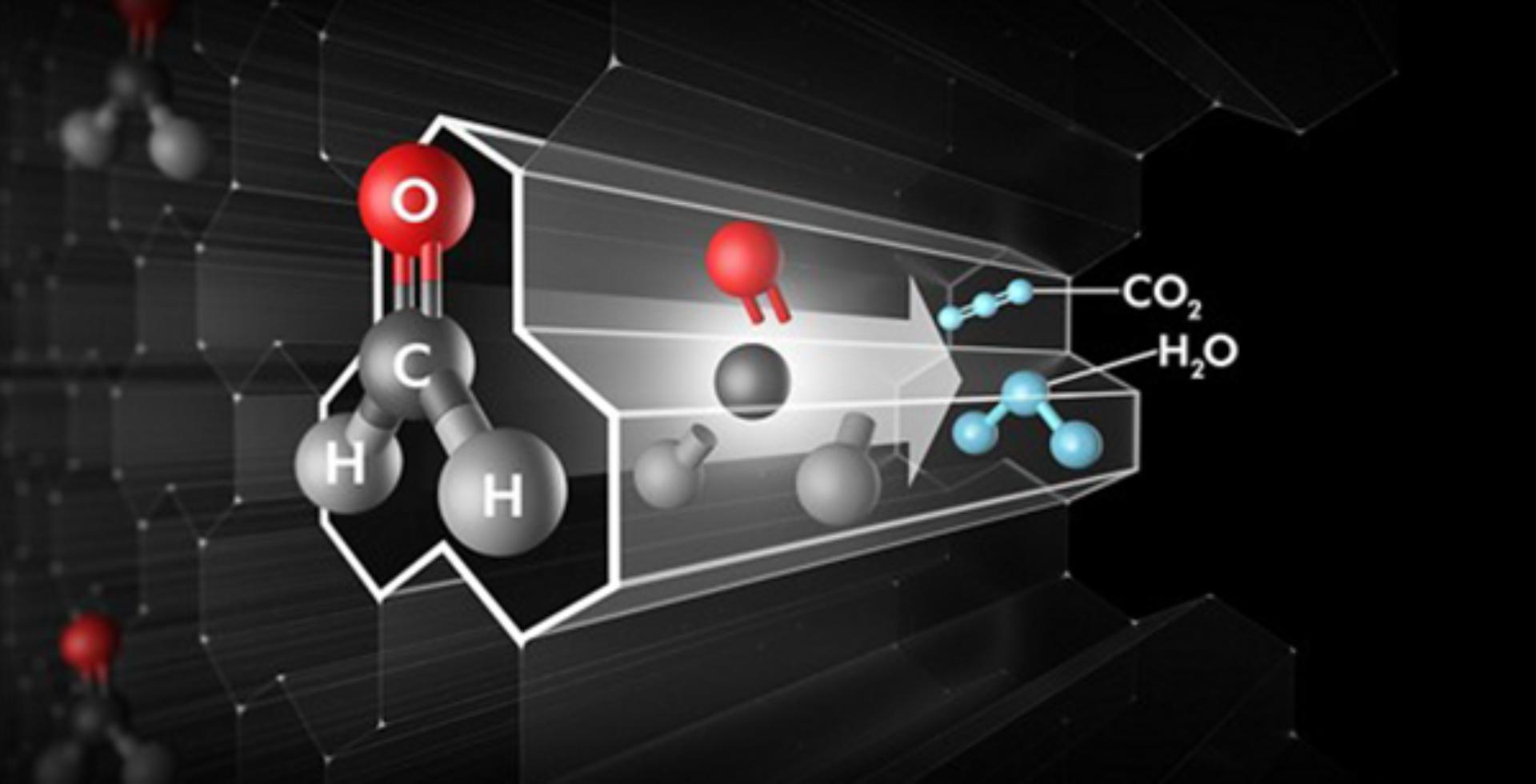

Dyson’s Selective Catalytic Oxidisation (SCO) filter continuously destroys formaldehyde at a molecular level.7 The catalytic filter has a unique coating, with the same structure as the Cryptomelane mineral. Its billions of atom-sized tunnels are the optimal size and shape to trap and destroy formaldehyde, breaking it down into tiny amounts of water and CO2. It then regenerates from oxygen in the air to keep destroying it continuously without ever requiring replacement.

Whole-machine HEPA filtration8

In Dyson’s new purifiers, it’s not just the filter that meets HEPA H13 standard, but the whole machine. The Dyson Purifier Cool Formaldehyde captures H1N19 and 99.95% of particles as small as 0.1 microns10 such as allergens, bacteria, pollen and mould spores.11 Dyson engineers took a forensic approach to achieving a sealed machine, creating high pressure seals at an additional 24 critical points to prevent dirty air from bypassing the filters and carrying pollutants back into the room.

Air Multiplier Technology

Using Dyson Air MultiplierTM Technology, the machine can project purified air to every corner of the room.12 Auto mode enables the machine to maintain a preferred room temperate13 and air quality levels, while the machine can be entirely controlled by the MyDyson™ App and activated by voice control.13

Engineered for real homes

Dyson Purifier machines are engineered for real spaces. The industry standard for testing air purifiers measures performance using a laboratory test conducted in a compact chamber 12m2 in size, with a ceiling fan to circulate the air and one sensor inside the room measuring air quality. For more representative testing, Dyson’s POLAR test is based on a larger room size of 27m2 with no added fan and uses eight sensors in the corners of the room and one sensor in the centre to collect air quality data.

[1] Particle challenge by DEHS oil specified in EN1822 within a chamber specified in ASTM F3150. Tested in Max Mode at IBR US, for whole machine efficiency above 99.95%.

[2] Third party full machine testing based on GB/T 18801-2015 formaldehyde cumulative clean mass testing with continuous injection until plateau of formaldehyde CADR is achieved. Results may vary in practice.

[3] WHO guidelines on indoor air quality: selected pollutants, World Health Organisation, 2010.

[4] Tested for filtration efficiency at 0.1 microns (EN1822, ISO29463).

[5] ‘How your lungs get the job done’ American Lung Association, 2017.

[6] ‘Combined or multiple exposure to health stressors in indoor built environments,’ World Health Organization Regional Office for Europe, Edited by Dimosthenis A Sarigiannis, pg 9, 2013.

[7] Third party full machine testing based on GB/T 18801-2015 formaldehyde cumulative clean mass testing with continuous injection until plateau of formaldehyde CADR is achieved. Results may vary in practice.

[8] 1 Particle challenge by DEHS oil specified in EN1822 within a chamber specified in ASTM F3150. Tested in Max Mode at IBR US, for whole machine efficiency above 99.95%.

[9] We challenged our purifier with airborne influenza A (H1N1 virus) at an independent lab. After 60 minutes in the chamber, at maximum fan speed, the airborne virus was reduced by 99%. Real-life efficacy may vary.

[10] Tested for filtration efficiency at 0.1 microns (EN1822, ISO29463).

[11] Markets to ensure they use appropriate caveats for their location

[12] In maximum setting. Tested for air projection (DTM 801) and purification coverage in a 81m3 room (TM-003711).

[13] Applies to heating function only.

[14] Requires device to run app, Wi-Fi or mobile data, Bluetooth 4.0 support, and iOS version 10 or Android version 5 (or above). Standard data and messaging rates may apply. Voice control requires compatible device.

ANZ Press Office

Email: aupressoffice@dyson.com